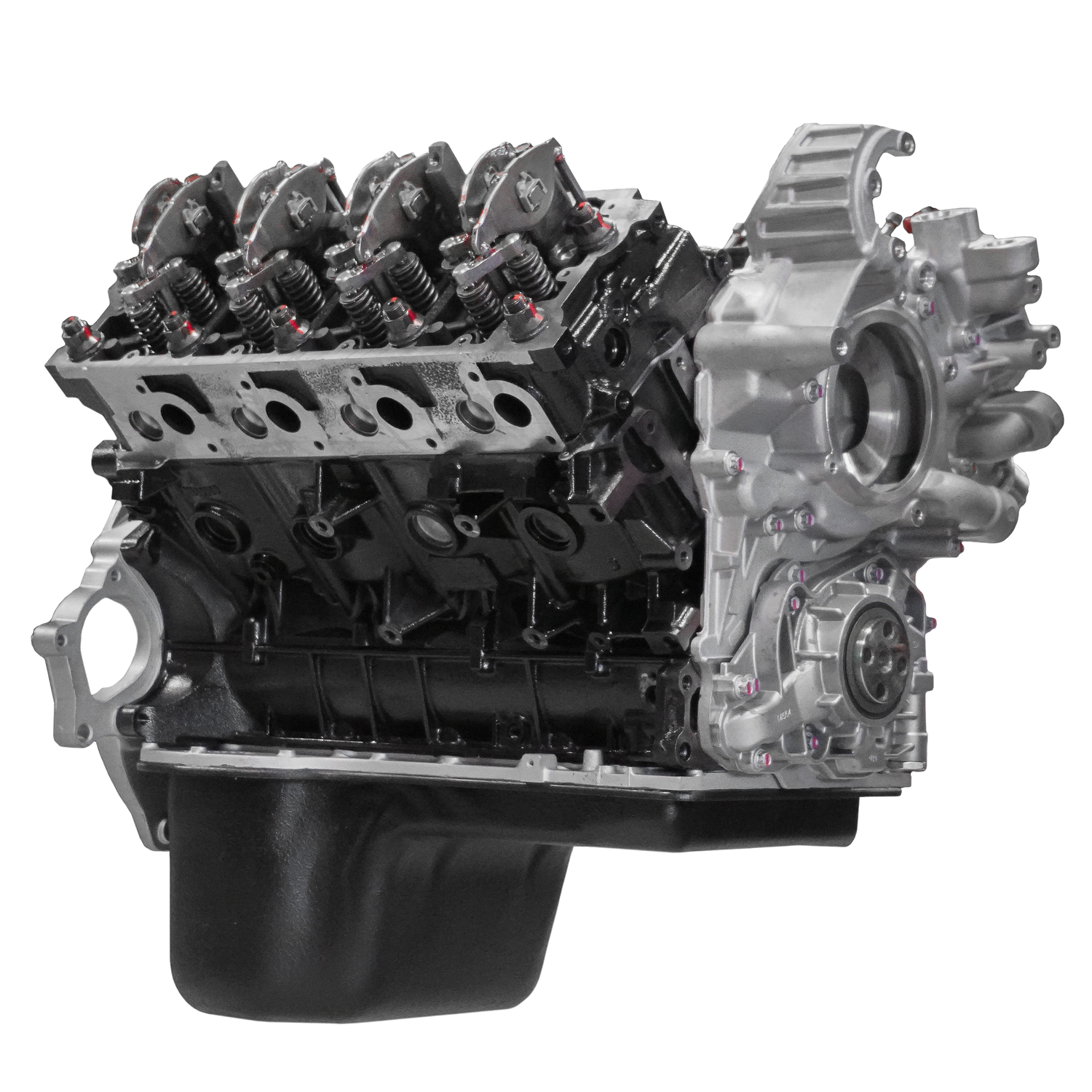

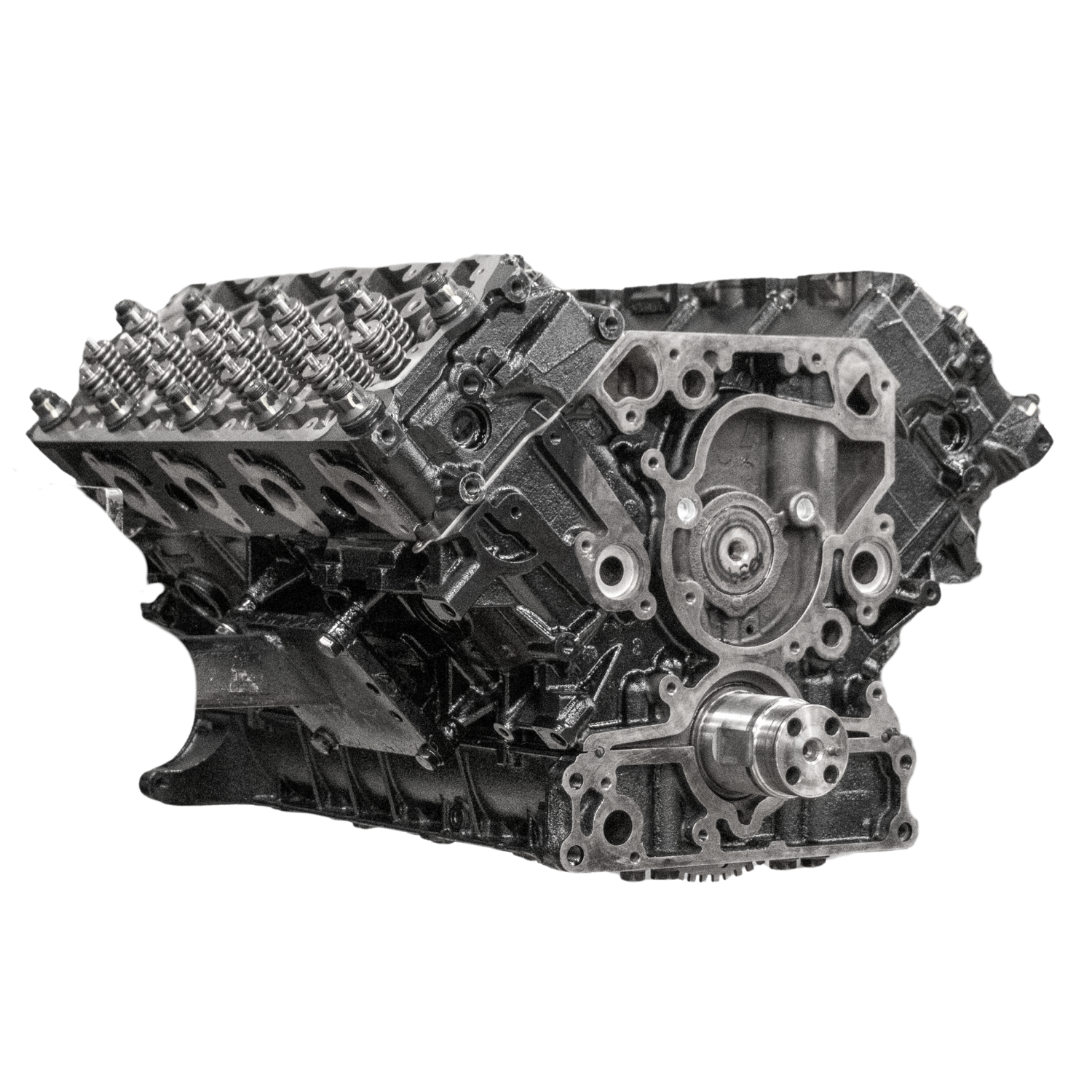

2008-2010 Ford Powerstroke 6.4L

SKU:64P-0810BTO-AM-BTB

Regular price

$9,499.00 CAD

Regular price

Shipping calculated at checkout.

- Bored & oversized diamond-honed cylinders & resurfaced block decks

- Mainline bores precision machined back to standard sizing

- Remanufactured heads with new guides and 3 angle seat cuts

- New Mahle Maxxforce 7 style pistons

- Precision-tested New valves & springs

- Assembled as a bare long block

- Block finished in high gloss black engine enamel

- Crankshaft, camshaft, pistons, rods, valves, & springs installed

Additional add-ons available upon request:

- HD valve springs

- Upgraded head studs

- Upgraded camshaft

- Upgraded pushrods

- Ceramic coated & delipped pistons

- Rotating Assembly Balancing available

Fill out the following to order your engine online

Inquiry Form

Features of this build

Engine Assembly

Blueprinting

Our process includes measuring and blueprinting all tolerances. The intent is to correct all of the small and large discrepancies within the entire scope of the engine assembly.

warranty

Built to last

When you build great engines, you can back them with great warranty. Click below to view our warranty for both commercial and non-commercial builds.

Built with the best components

- Choosing a selection results in a full page refresh.